THE MOST ADVANCED GLASS PRESS MOLDING SOLUTION

THE MOST ADVANCED GLASS PRESS MOLDING SOLUTION

The Nanotech 170GPM is a glass press molding machine designed for precision glass optic applications in both wafer and individual lens form. It features a single molding chamber with a 170mm diameter capacity. This machine complements Nanotech’s 450UPL and 650FG systems which can be configured for ultra-precision grinding of mold components in various materials such as WC and SiC. Together, the combination of systems forms a next generation glass press molding cell.

Major Upgrades

- Chamber size increased from 140 to 170 mm diameter

- Maximum pressing force increased from 25 to 40 kN

- Maximum vacuum increased from 1300 to 0.6 Pa

- Heating capacity increased from 8.5 kW to 19.2 kW

- Nitrogen flow capacity increased to 500 liters per minute

- All new robust Controller & Software for industrial reliability

Additional Features

- New PID cooling cycle

- Operation and maintenance simplified by reduction of wear parts by 25%

- Lamp life monitoring

- Lamp cartridge design for quick lamp changes

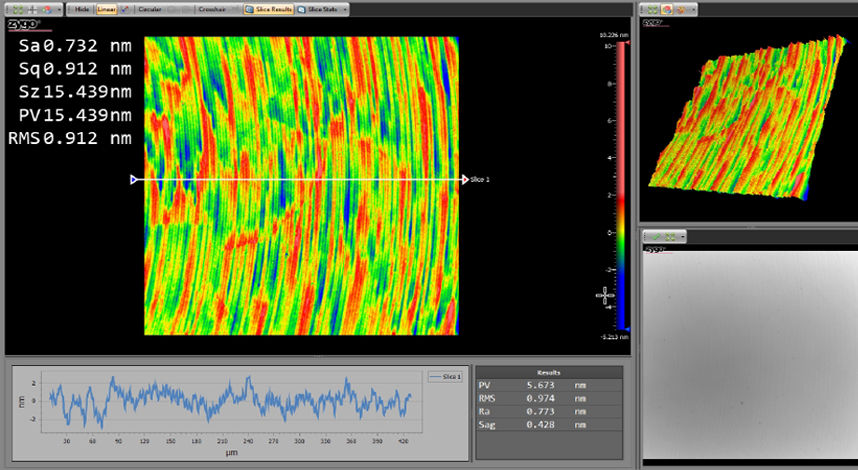

WE QUANTIFY RESULTS THE WAY YOU DO!

Always measured on the same surface, after same finish pass.

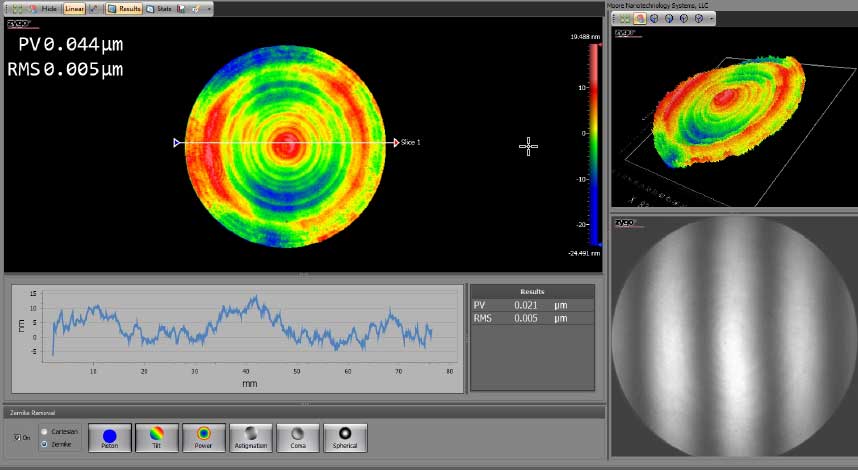

Sub-nanometer Surfaces Finishes, Sub-micron Form

Directly Off the Machine in a Wide Variety of Materials!

Diamond Turned XZ Standard Acceptance Test Part